5 years FIDLOCK Bike – The Story

On the occasion of the EUROBIKE 2021, we look back on five years of FIDLOCK Bike – in the summer of 2016, the first TWIST bottle was presented at that Eurobike show and thus, the FIDLOCK Bike story began. But what was the path to the first TWIST bottle like and what hurdles did we have to overcome? Find out here!

FIDLOCK’s mission to make the moment of opening and closing special, not only led to the founding of FIDLOCK, but was also the cornerstone for the revolutionary FIDLOCK Bike products. Since there were always bike-crazy developers working at FIDLOCK, it was clear pretty quickly that this closure system must somehow be connected to the bike. An intuitive and secure bottle cage for bikes without the bulky size or wobbling of a bottle in a cage, was an exciting idea. So the plan was born to take advantage of the magnetic and mechanical system to hold a bike bottle.

The first task was to develop a system that could be attached in one swift motion and remain securely attached to the bike on bumpy roads. After much brainstorming, the answer came from an earlier FIDLOCK magnetic closure, the TWISTER. As the name suggests, the archetype’s functionality is based on a twisting motion which prevents the bottle from falling off while jumping or riding over cobblestones.

Many ideas were tested and the nerves of our developers strained. “Above all, connecting the bottle to the cap was a challenge. After testing many different options, we came up with ultrasonic welding. Without this very first solution, we probably would never have been able to create a TWIST bottle,” Friedemann recalls, who helped develop the bottle. “In addition, testing the bottles was not at all easy. Since the prototypes from the 3D printer did not have the same material as the final product, we couldn’t test the bottle’s resilience and applicability until we had the finished tool. It was a close call – the first bottle ready for testing fell out of the mold just a few days before Eurobike 2016,” he tells us. Friedemann still remembers the uncertainties the team faced at the time: “Even though we were excited about the technology ourselves, there was still the question of how our customers would react to this completely new type of bottle holder. Would the system be understood immediately and would the benefits be recognized? So the excitement grew enormously before EUROBIKE 2016 – before the very first presentation of the TWIST bottle.”

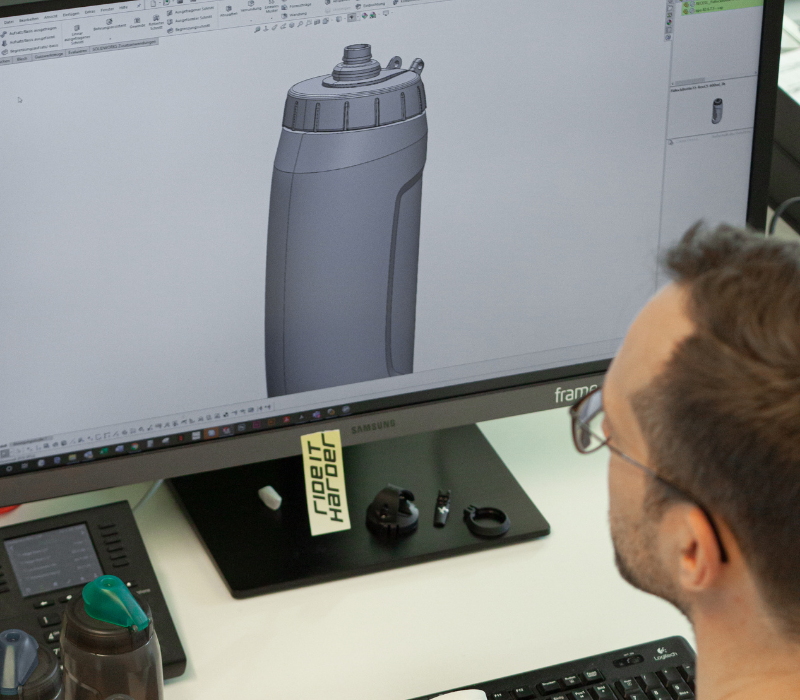

Our TWIST bottle 450 at a glance

Now that additional sizes were well received, our developers continued to optimize the original challenge of connecting the connector and bottle. To be even more resistant, especially for the rough trails in the mountains, a new type of connection was needed. After much searching and testing, a production opportunity arose in Italy that allowed for the new “overmolding” technology. With this technology, the connection to the magnetic-mechanical connector can now be molded into the bottle while the bottle is still being blown. This type of process replaces ultrasonic welding and eliminates the need for the Gravity Kit. Of course, the new bottle was immediately updated with an ergonomic design and a new lid with an optional dirt cap.

But the bottles were not enough – the TWIST product family was also expanded to include the toolbox and the uni connector. And the reward was not long in coming: the TWIST uni connector was awarded our very first Design & Innovation Award. The success confirmed the motivation to optimize even more bicycle products with a FIDLOCK system. This is how not only PUSH and HERMETIC came into being, but also the revolutionary VACUUM system!

With VACUUM, a whole new world of closure principles entered the FIDLOCK universe. Because VACUUM does without the usual magnet-mechanical technology of FIDLOCK and combines the power of a vacuum with magnetic force for the first time. Birth of an innovative and safe smartphone holder for the bike, which won a second Design & Innovation Award. But just as TWIST did not stop with a bottle, the VACUUM phone mount will not only consist of a few products for the bicycle sector, but will become an all-rounder for everyday life – promised!