Custom development of fastening and mounting systems for special requirements and unique products

Experiencing the unique functionality and ease of use of the FIDLOCK concept is not only limited to opening and closing a fastener, but can also be adapted to the moment of connecting two parts. We offer our expertise in projects for unique adaptations, since using a catalogue part won’t suffice for some applications. On top of that, our technology can be integrated invisibly into your product, offering a unique user experience and reliable features. Be it for fastening, connecting or attaching – continue reading to find out more about an individual development project with FIDLOCK to create an innovative component for your products! Alternatively, you can check out examples in our stories:

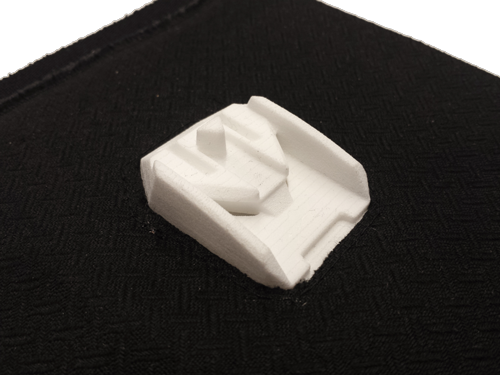

The PRO tank ring for the SW-MOTECH fastening system for luggage was developed in an individual project with FIDLOCK.

Our development expertise also includes electrical connections, creating completely new, exciting possibilities. Great examples are the MonkeyLink light modules and accessories for e-bikes and bicycles.

Electric connections for MonkeyLink

Customized development process

The following content is dedicated to giving a detailed overview of the process if you decide to request a development project with FIDLOCK. The possibilities for development projects include adapting existing structural components or completely constructing new products with FIDLOCK technology.

Briefing:

At the beginning of each development project, FIDLOCK composes a briefing to record the requested task and the goal of the project. Here, researching comparable products helps to define features with additional values for your customers. Additionally, we discuss which deadlines we need to consider for you and other involved service providers.

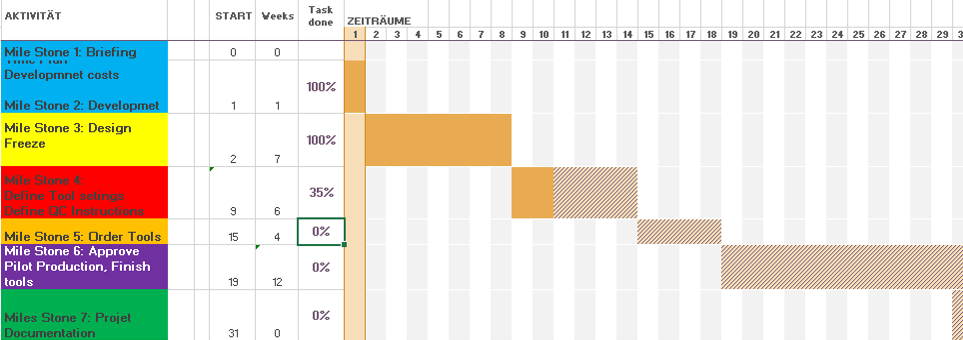

Planning:

Considering our experiences of the past, our next step is to generate a timeline and cost estimate for your project. This includes timeframes for each step and the effort for our development team. Additionally, test periods, criteria for component approval and the individual approval processes for FIDLOCK and the customers influence the planning.

The first milestone of your individual project is reached when both parties have agreed on a briefing and timeline. The second milestone of each project is the development, including the following steps:

Text Sketches

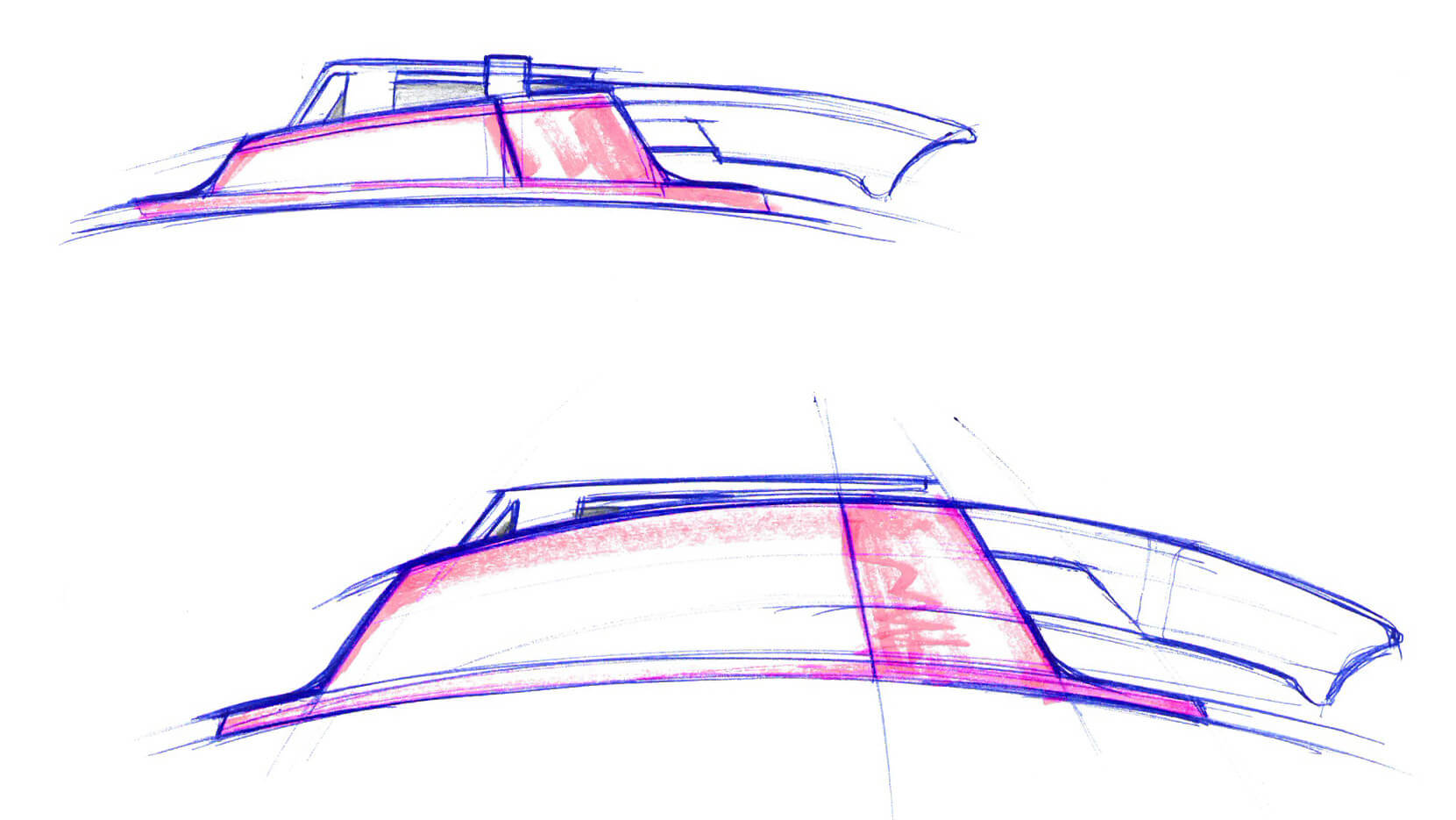

Concept sketches:

Next, our team starts visualizing possible concepts to estimate the size and operation of the components. We will create multiple concepts for you to choose from and discuss the possibilities.

Text Konzepte Testen

Testing concepts:

Considering the preferred design, we will create different 3D models to test the mechanics and functionality of the parts and evaluate proportions. You will receive prototypes to approve the features defined in the briefing.

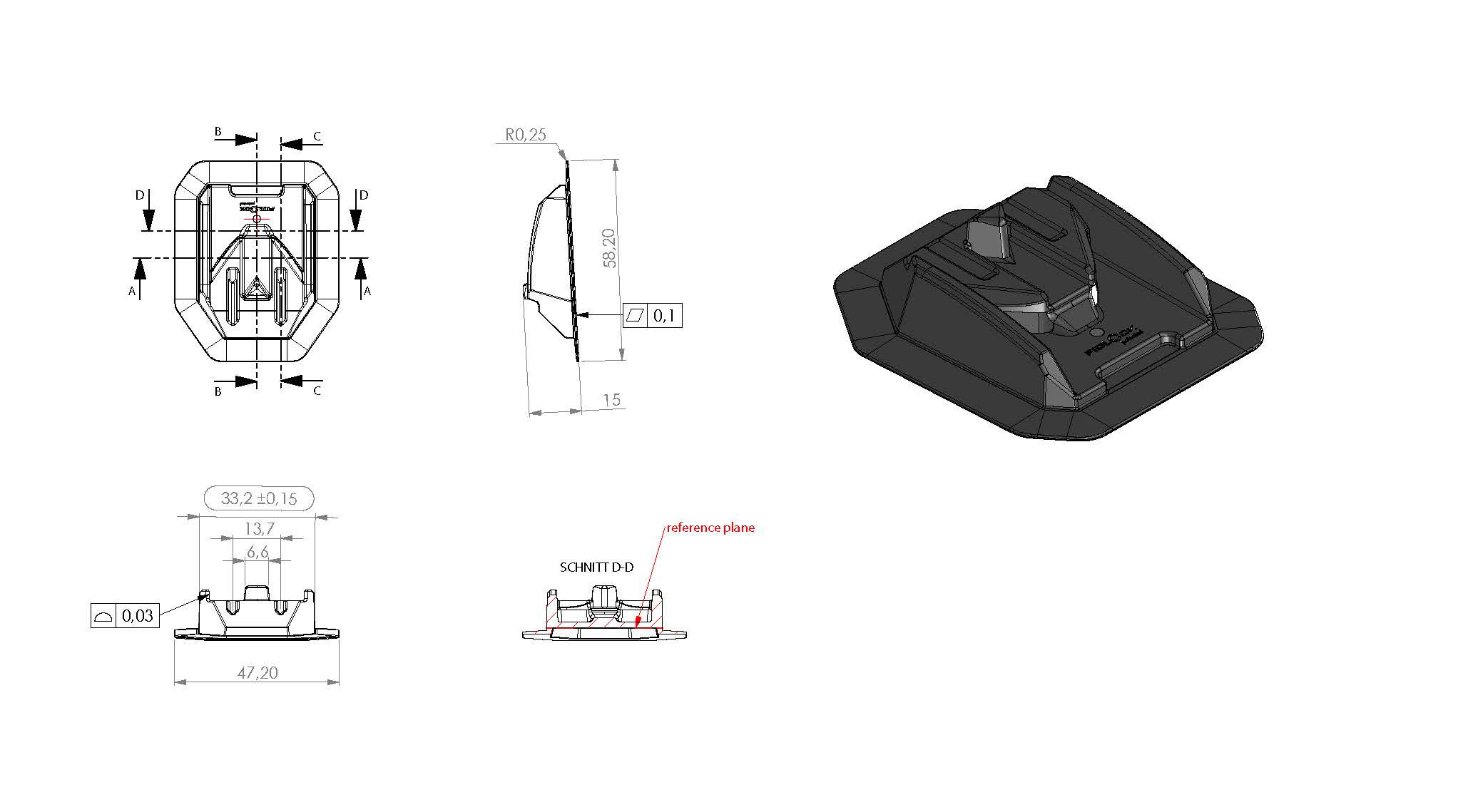

Text CAD Construction

CAD construction:

Our development team will test producibility, function and stability of the parts during the construction, discussing needed enhancements or solutions with the customer. Afterwards, we will construct the final design in a CAD-System and calculate the tool costs with the received data.

After you approve the parts and costs, we will freeze the design process and continue with the tool preparation, reaching the third milestone of the project.

Text Element

Tool preparation:

Our team will create 2D and 3D data which are suitable for production. FIDLOCK will discuss adjustments of the parts needed for production with our or your tool manufacturer. Additionally, our team will define the quality control process for series production.

With the tool preparation, you have already reached the fourth milestone. The fifth milestone follows when the tools are ordered.

Tool production:

FIDLOCK will look for suitable suppliers needed for the production. Tool configurations, such as material, parting lines, ejector pins positions, injection points and life span are discussed in cooperation with the customer. We can also monitor the process and offer support, should you decide to produce the tools yourself. First shot samples will be reviewed by our team, finding solutions if needed.

Approval process:

Finally, we will start the pilot production of 500 to 1000 pieces to review the process. We will test some of the parts in our laboratory which includes traction, dynamic strain and climate testing. Additionally, custom examinations are possible, and you will receive parts from the pilot production for own tests.

When we get your approval after testing, the sixth and virtually final milestone is reached and your application with FIDLOCK technology is ready for series production! At the end of each project, we go into concluding project documentation which can be seen as an additional and finalizing milestone for each project.

If this page has spiked your interest in an individual project with FIDLOCK or if you have any further questions, our service team is happy to help!

© SW-MOTECH

Do you want to learn more about the possibilities? Then check out our story about the attachment for the PRO tank bags that we developed in an individual project with SW-Motech.

Are you interested in electrical components? You can learn more about electrical connection modules by FIDLOCK in this story using our development for MonkeyLink as an example.